Moving to MediaCityUK has many perks and one of them is the sheer number of events that are held each week in the digital hub! One we were lucky enough to attend was the Canon 3D printing seminar at The Landing last Wednesday.

The Landing gives digital SMEs and micro-businesses a place to work alongside large media and technology organisations, allowing them to be part of and benefit from the exciting and rapidly growing community at MediaCityUK.

The Landing is home to one of Barclays Eagle labs. Eagle labs have been set up around the country providing creative technology facilities to help small businesses expand their offering without the huge outlays of new equipment which can often cripple a small business and even stifle what they can do. It was great to be shown round the Eagle Labs and after meeting the team behind it, it definitely got our imagination flowing for potential new offerings for our clients too!

Eagle Labs @ The Landing will provide co-working space, access to expert mentoring networks, funding partners, event space and Digital Fabrication equipment giving start-up businesses and scale-up communities a crucial boost.

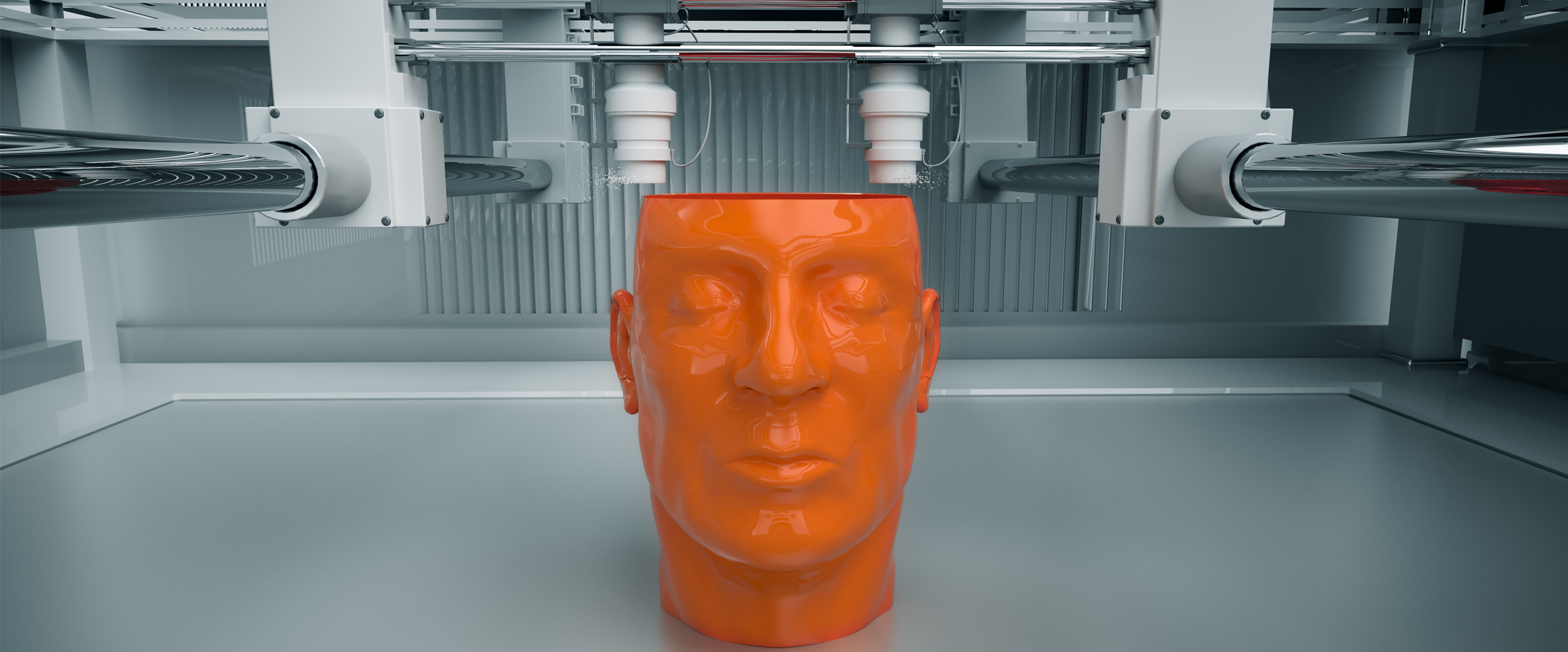

After an introduction from Canon about the business services, which range from small in-office printers to huge medical imaging equipment, Canon are now working in partnership with 3D software developers to support the 3D printing technology for their customers. For us at Carbon, this was a great opportunity to be nosey and see what is available, so that we have a better understanding in what we can offer to clients as this technology is becoming more well-known. It is no longer limited to prototyping in the manufacturing industry, which is very exciting to a creative agency!

The day consisted of checking out the latest in live 3D scanning which enables people to create a real-time mesh, and then convert that to a printable object. This kind of method is fantastic if you want to recreate an object that has not previously been printed, and rather than spend time rendering a 3D model on software, the scanning technology instantly cuts/reduces that part of the process.

We also got to see two different types of 3D printers, one with powder and ink that prints in colour (just like a normal printer), and then an acrylic resin printer that prints in white. We learnt about the different structural support that the printers use. One being powder and the other wax! It was a great day and one we were pleased to be part of, we can’t wait to see what comes next of all our 3D printing technology knowledge!